Thank you for your interest in our innovative product. During the early years when we were developing PunctureSafe, our research revealed that there was a need for a good quality puncture prevention treatment for very high speed vehicles that would provide a permanent seal and would last for the lifetime of the tyre, but at that time there was no such product available. We believed that the sealants on the market were only suitable for slow moving construction industry vehicles and large trucks because large wheeled, low speed vehicles do not generate heat, stress or centrifugal forces that will eventually cause most tyre sealants to break down or pull apart. We looked worldwide at the tyre sealant industry that had developed over the years and after exhaustive testing we found that the large majority of tyre sealants available did not work satisfactorily, indeed many caused other problems inside the tyre. We did not find a tyre sealant with the unique abilities and attributes that we currently find in PunctureSafe, but more alarmingly we discovered that many tyre sealants contained Ethylene Glycol as an anti-freeze which is lethal to humans and animals. Many tyre sealant manufacturers worldwide are still using old technology and out-dated polymers developed many years ago, still mixing their ingredients in a food industry mixer like a giant yogurt recipe without the application of heat. It is our opinion that a quality permanent puncture prevention treatment cannot be made without the application of heat and the principles of chemistry, for in order to incorporate all the attributes necessary for a good product, we believe the ingredients cannot be mixed cold.

I had worked extensively in the laboratory for several years with the many specialty polymers that were being developed for industry. As such my experience with heat resistant polymers led me to believe that we could overcome the difficult task ahead and develop a high performance permanent puncture prevention treatment that would be both fit for purpose and able to survive the hostile environment inside a high speed tyre. We are a responsible company, conscious of health, safety and the welfare of all things living so therefore our puncture prevention would also have to be formulated with a non toxic anti-freeze that would be just as effective as a Glycol. After a decade of development and exhaustive testing we successfully managed to achieve all our goals. With 21st century polymers, modified by ourselves from selectively chosen raw materials and cutting edge chemistry, in a proprietary process developed exclusively in the UK, we now manufacture a premier high performance high speed permanent puncture prevention treatment. The most challenging part of formulating for high speed vehicles was to incorporate the ability of the sealant to thinly cover more of the the inner tyre "with increasing speed" instead of being driven by centrifugal forces in a very narrow band down the centre of the inner tread area. Using "chemical nanotechnology", we invented a polymer gel that we trademarked "FlexxaGel™" that had an extraordinary ability to cling to rubber under all conditions, even at speeds of 250 kph. Incorporation of FlexxaGel™ into the process also gave the finished sealant incredible elastic properties enabling it to stretch and flex at the higher speeds. FlexxaGel™ is exclusively manufactured at our Devon facility and is one of our most closely guarded trade secrets.

Our proprietary formulation has evolved far beyond that which is commonly known as a tyre sealant - PunctureSafe is a tyre safety system that is outstanding at permanently sealing punctures and a true tyre life extender. The complexity of the formula, the proprietary polymers processed in-house and the high tech chemically engineered processing equipment required for manufacturing such a product means that no other company has yet managed to duplicate, or get close to what we have accomplished. With the knowledge achieved developing our high speed product we have managed to achieve unbelievable success with our low speed extra heavy duty grade which is outperforming everything else by huge margins. We manufacture 4 different grades which are packaged comprehensively for all markets. It has been the combination of an excellent product, consumer friendly packaging, informative point of sale material, and full back-up support and equipment that has given us so much success.

Worldwide Master Licence Holders. Following our phenomenal success in the UK we are now receiving numerous enquiries for PunctureSafe from all around the world and are now in the process of appointing overseas Master Licence holders. In only 2 years since we decided to go global PunctureSafe is now represented extensively worldwide. Prior to this we refused to supply overseas so as we could focus totally on our UK market. We get enquiries daily for distribution of this unique product from all parts of the world and from the remotest of locations such as Katmandu, Nepal (next to Tibet) in the Himalayas!

Apply: Any company or individual in a country where PunctureSafe is not established is invited to submit a proposal to join the PunctureSafe team as an International Distributor. We do not charge a fee for this licence, but we do require that Master Licence holders have an excellent business capability and track record, with good finances in order to successfully build a solid PunctureSafe business. We are interested in sharing our knowledge and expertise with enthusiastic people who can duplicate our success in their own country. We can get you up and running quickly because we have all the equipment and master software which has taken us many years to build. If you can meet all our expectations please e-mail or call for an application form.

As head of Research & Development and with very extensive knowledge of advanced polymer chemistry, I will ensure PunctureSafe remains the world’s “number one” high performance permanent puncture prevention treatment for high and low speed vehicles well into the future.

We are a victim of our success. Due to our spectacular progression during the last 20 years because of the quality of our tyre sealant, others have tried to cash in on that success. Overnight, individuals have appeared with very impressive web sites, looking like they are a “big company” hiding the fact they do not manufacture the tyre sealant they are selling under a “made up tradename”. It is a fact that there are only 11 tyre sealant manufacturers in the entire world, the majority of whom make sub-standard sealants, and they will sell to anyone, at any price. This has caused the creation of hundreds of worldwide tyre sealant resellers giving rise to the myth that there are hundreds of tyre sealant manufacturers. Anyone with website building knowledge and a skill with Photoshop, can, overnight look like they are manufacturing a quality tyre sealant and also give the impression they have been trading for many years.

We get visitors to our manufacturing facility who are absolutely amazed at what they see, due to the fact that previously they have visited what they thought was a “so called tyre sealant manufacturers” in the UK, only to be hosted in people’s houses or in hotel lounges because there was no manufacturing facility. On many occasion’s when there was, these visitors (to us) have also reported visiting tiny and dirty industrial units on scruffy industrial estates were the tyre sealant was mixed in restaurant sized 20 litre food mixers and at one particular run down building, mixing was done in a 30 litre yellow builders cement mixer, but the companies in question have amazing websites with exaggerated claims. These companies have absolutely no research and development behind them, they are just interested in cashing in on our success. The problem is the market gets flooded with sub standard products with an extremely high liquid/water content and the many testimonials given to these companies were given before their product failed.

We strongly recommend that before a substantial investment is made with a supplier of a tyre sealant, that you visit their premises or at least ask that question “if I visit you will I see a substantial manufacturing facility, if any at all”, but we strongly recommend you visit any potential tyre sealant company for peace of mind. It is against the law in the UK to put something on your website if it does not exist, so if a website shows substantial premises with mixing tanks then it probably does exist, if not, then it does not exist, or it is not worthy of publication.

We are proud of our manufacturing/warehouse/office facility which has grown substantially over the years due to the quality of our tyre sealant, but it has come at a price because what we see appearing "overnight" are new "SO CALLED tyre sealant manufacturers" with attractive websites containing plagiarism, because in-depth technical content from our website that took years to establish with exhaustive testing, is appearing all over other reseller websites.

Ian (above left) our National Account Managerwith our Works Manager

Our factory/distribution warehouse (above)dispatches UK and international orders.

Our Russian distributor (above left) one of our overseas MasterLicence holders on one of her many visits to the UK.

As a new supplier to their maintenance workshops, in partnership with our distributor in the NW, we were proud to be Invited to exhibit on the Speedy Hire PLC stand to demonstrate our sealant to Speedy Hire suppliers and customers. The HGV tyre above had a 15mm diameter spike hammered into it over 100 times a day and did not suffer any loss of air pressure.

We have the equipment to give full back-up support no matter what the request may be.

The PunctureSafe UK research and development team (above) who developed PunctureSafe, have advanced knowledge of polymer chemistry in their individual fields of expertise which helped make PunctureSafe a truly unique product.

Our manufacturing process plant (above) comprises up to date equipment that produces batch to batch consistency.

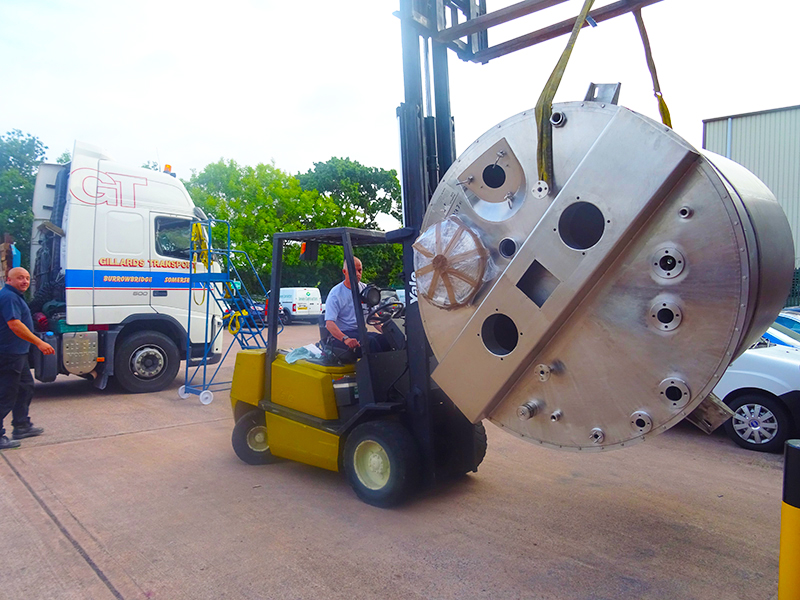

September 2017 - Our new process tank is finished to our exact specification at the tank manufacturers after a year long wait and now delivered to our Exeter Factory to have all the mixers and other process equipment fitted by our specialist engineers.

Mr Haji-Jassim one of our Middle East distributors (above left) helping with the safe off-loading whilst management was busy hosting visitors, during one of his many visits to our headquarters to organise the contracts and certificates of authenticity for the Master Licences.